The camshaft is essential to an engine's operation and efficiency in the intricate world of automobile engineering. Engine enthusiasts and professionals often ask, "What is a camshaft?". This question highlights the ingenuity and intricacy of internal combustion engines. The engine's intake and exhaust valves are controlled by this crucial part, directly influencing efficiency, speed, and power output.

This article will explain the basic principles of camshafts, including their function, structure, and technological developments, offering useful insights into why they continue to be a vital component of engine design.

What is a Camshaft?

A camshaft is a long bar with eccentric lobes that resemble eggs. Camshaft lobes control the intake and exhaust valves in engines without a common rail fuel injection system. In many earlier diesel designs, distinct lobes also powered mechanical fuel injectors.

If the engine does not have a common rail fuel injection system, each cam lobe represents a valve and fuel injector. Each lobe has a follower that is forced up and down as the camshaft rotates, following the profile of the cam lobe.

Various connections, known as pushrods and rocker arms, connect the followers to the engine's valves and fuel injectors. The reciprocating motion generated by the camshaft lobes is transmitted through the pushrods and rocker arms, which in turn open and close the valves and injectors as needed. The rocker arms drive the valves open, and then springs seal the valves once more.

The primary components of the camshaft system, their roles, and locations in various engine types are outlined below:

Valve Train: Camshaft lobes generate motion transmitted via pushrods and rocker arms; valve springs store energy to close valves; valve lash allows thermal expansion.

Idler and Timing Gears: Synchronizes camshaft rotation with crankshaft; ensures precise timing for valve operation and fuel injection; multiple camshafts may be used for performance or efficiency.

Number and Location of Camshafts: In-line engines: camshaft in head or block; Small/mid V-type: camshaft in block at centre of “V”; Large/multi-cam V-type: camshafts in cylinder heads.

Purpose of a Camshaft

The purpose of the camshaft is to control valve timing, engine efficiency, and performance. The camshaft coordinates the timing of valve motions to guarantee smooth functioning and effective combustion. Its function extends beyond merely opening and shutting valves, enhancing efficiency.

1. Controlling Valve Timing

The main purpose of the camshaft is to regulate the intake and exhaust valves’ opening and closing throughout the engine cycle. Precise valve timing guarantees efficient expulsion of exhaust gases and the timely entry of the air-fuel combination into the combustion chamber. Engine damage, decreased performance, or decreased fuel efficiency can result from any misalignment.

2. Synchronization with the Crankshaft

The camshaft aligns with the crankshaft through timing gears, chains, or belts. This synchronization ensures that piston travel and valve movements properly match, maintaining the correct engine cycle. The camshaft normally rotates at half the crankshaft's speed because the exact motion of the camshaft is essential for attaining the best engine RPM performance.

3. Influencing Engine Performance

The angle and form of the cam lobes determine the length of time the valves remain open. It impacts the engine torque, power, and efficiency. Hence, it is possible to optimize camshaft design for several RPM ranges. For example, low RPMs increase torque and fuel economy for daily driving, and high RPMs optimize performance and power for heavy-duty or racing applications.

Modern engines frequently use variable valve timing. VVT enables the camshaft to dynamically modify valve timing for maximum performance across a broad range of RPMs.

4. Beyond Valve Control

To further increase combustion efficiency and lower emissions, the camshaft in some engines may also have an impact on other systems, such as valve overlap or fuel injection time.

Common camshaft problems and repairs

Many issues may affect how long the camshaft lasts, such as the engine's design, the premium materials used, maintenance procedures, and driving circumstances. Camshafts usually last hundreds of thousands of miles in well-maintained engines with frequent oil changes using the appropriate oil and filter from the manufacturer. Some top-notch engines can even go up to 200,000 miles (about 322,000 kilometres) or more before needing a camshaft replacement.

However, the following is a list of potential red flags to watch out for:

Lobe scoring:

The camshaft lobes may get scored as a result of excessive wear or poor lubrication. This may cause harsh operation and damage or misalignment of the valve.

Camshaft bearing failure:

Unpredictable camshaft movement brought on by worn-out or failed bearings might result in engine noise, as well as possible engine damage.

Improper timing

Incorrect valve timing can lead to poor engine performance and higher emissions. It can also occur from faulty synchronization with the crankshaft.

Leaks from camshaft seals:

The camshaft is frequently sealed to stop oil leaks; however, if the seals fail, the engine may run on low oil levels or oil leaks.

Camshaft sensor problems:

Not all engines have sensors. Faulty sensors may result in inaccurate timing information or misreadings, which can impact engine performance and trigger issues.

Broken or bent camshaft:

The camshaft may break or bend under high mechanical stress situations or in the event of an engine failure. This malfunction necessitates prompt attention and frequently leads to engine damage requiring costly repairs.

When combined, these issues may result in a reduction in engine performance, odd noises coming from the engine, and, in extreme situations, engine failure.

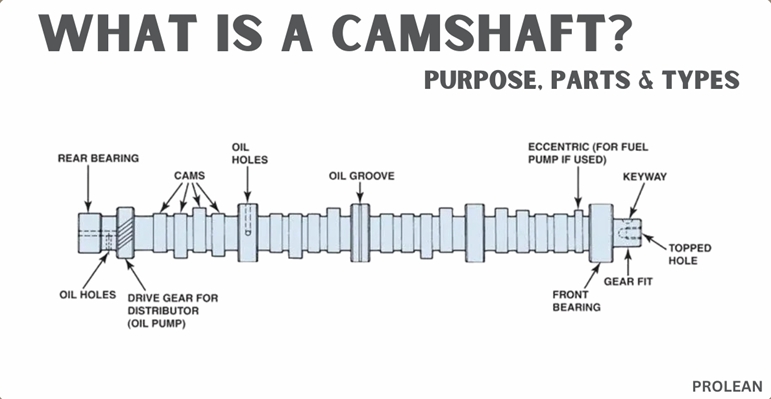

Parts of a Camshaft

The camshaft, like other auto parts, is made up of several parts, some of which are as follows:

Cam: The most crucial component of a camshaft is the cam. It is in charge of the valves' opening and shutting.

Cam follower: The portion of the camshaft that has been driven is called the cam follower.

Driveshaft: This characteristic allows the whole camshaft structure to move. It can operate independently or be connected to another engine component known as the crankshaft via a belt.

Shaft: This holds the camshaft together and serves as its supporting element. When the combustion engine is operating, it can withstand demanding workloads.

Bearings: Bearing is also a crucial part. This component ensures that the shaft is positioned upright. Because it aids in lowering friction when the camshaft is operating, it also comes with a unique tool for changing the camshaft's oil.

Lobes: The camshaft may interchange fuel-packed gases due to its structure. Additionally, the engine's speed also controls the lobes' speed.

Chain sprocket: The camshaft is connected to one end of the chain sprocket. Furthermore, the timing belt and chain sprocket assist in maintaining synchronization between the crankshaft and camshaft.

Types of Camshafts

There are two categories for camshafts: material or construction type and engine design. Engine durability, efficiency, and performance are all impacted differently by each kind.

1. Single Overhead Camshaft (SOHC)

An internal combustion engine (ICE) design known as a single overhead camshaft (SOHC) has a single camshaft situated in the cylinder head, directly above the valves. More accurate valve timing and increased engine efficiency are made possible by this camshaft, which regulates intake and exhaust valve actions.

Automobiles, motorbikes, manufacturing vehicles, and some industries use SOHC reciprocating engines. Compared to double overhead camshaft (DOHC) engines, they are more affordable and have a simpler production process, which makes them popular. Despite its lack of efficiency, SOHC engines may provide a respectable power output for most applications.

2. Double Overhead Camshaft (DOHC)

DOHC stands for Dual Overhead Camshaft. However, some may refer to it as a double overhead camshaft. However, it simply indicates that the engine has two camshafts. One operates the exhaust valves and the other opens the intake valves, perched above the cylinder head. The engine can breathe more precisely because of the direct control over the intake and exhaust valves, which results in cleaner combustion and more useful power.

3. Pushrod (Overhead Valve) Camshaft

The camshaft of a pushrod engine, commonly known as an overhead valve engine (OHV), is housed inside the engine block. In order to open and close the valves, the cam lobes push lifters, which in turn move pushrods that rock the rocker arms.

Pushrod engines are perfect for trucks, off-road vehicles, and street-driven performance cars because of their reputation for producing powerful torque at low RPMs.

Camshaft Types by Material and Design

4. Flat or Tappet Camshafts

The most commonly used camshaft setup nowadays is the flat tappet design. Where the lifters have a flat surface that rides on the cam lobes.

The most basic and widely used camshafts nowadays are flat or tappet camshafts. They feature a level surface that the lifters or tappets travel on. Regular maintenance of the flat or tappet camshafts is necessary due to wear and tear, including the replacement of lifters and camshafts occasionally.

5. Roller Camshafts

These cam lobes use roller bearings, which lessen wear and friction during operation. High-performance engines frequently use them because they are more resilient than flat or tappet camshafts and can handle higher RPMs and valve lift. According to ProleanTech, roller camshafts are preferred in performance engines because they have less friction and handle higher RPMs.

6. Cast Iron Camshafts

Older automobile engines often used cast-iron camshafts due to their affordability and robustness. They have long been preferred because of their durability and wear resistance. But steel billets or forged camshafts are a better choice for high stress and high RPM applications than cast iron. . They have long been preferred because of their durability and wear resistance, which makes them better choices for high-stress engine applications.

7. Steel Billet Camshafts

Steel billet camshafts are machined from a single, solid piece of premium steel. They are exceptional because of their remarkable strength and accuracy. The primary benefit of steel billet camshafts is the customizing of every component, including lift, duration, and lobe shape. This enables engine engineers to precisely adjust the timing of the valves for optimal power, torque, and efficiency at particular RPM ranges.

Because of their exceptional resistance to wear, heat, and stress, billet camshafts are perfect for engines running in harsh environments, unlike cast iron or conventional roller camshafts.

Camshaft in Modern Engines

Both camshafts and modern engines have undergone substantial change. Modern camshaft designs prioritize improving engine performance, efficiency, and emissions management in addition to opening and shutting valves.

Variable Valve Timing (VVT) is one of the most significant developments. With the use of this technology, the camshaft may dynamically modify the timing of valve opening and shutting in response to changes in engine speed, load, and RPM. VVT enhances power production, lowers hazardous emissions, and improves fuel efficiency with real-time valve timing optimization.

Another trend in contemporary camshaft design is the use of lightweight, high-strength materials, such as steel billet or sophisticated alloys, which increase durability while lowering rotational mass. In order to reduce friction and enable greater RPM and smoother operation, certain high-performance engines also use roller camshafts.

In order to improve combustion efficiency, enhance airflow, and precisely manage intake and exhaust valves, modern engines may also include several camshafts per cylinder bank, such as DOHC systems. Furthermore, several trucks and SUVs still employ cam-in-block designs (OHV) since durability and torque are more important than high RPM performance.

Camshafts are now precision-engineered systems that directly affect engine power, emissions, and efficiency. As such, they are an essential component of modern automobile engineering and are no longer only mechanical parts of engines.

Final Thoughts

An essential part of every internal combustion engine, the camshaft coordinates the exact timing of valve motions to guarantee maximum longevity, performance, and efficiency. Depending on the needs of the engine and its intended application, each type of camshaft offers distinct benefits.

Through innovations like variable valve timing and sophisticated materials, modern engines have further improved camshaft operation, enabling increased RPM performance, lower emissions, and better fuel efficiency. Anyone hoping to maximize engine performance or properly maintain their car must comprehend these advancements.

Media Contact

Company Name: ProleanTech

Email: Send Email

Country: China

Website: https://proleantech.com