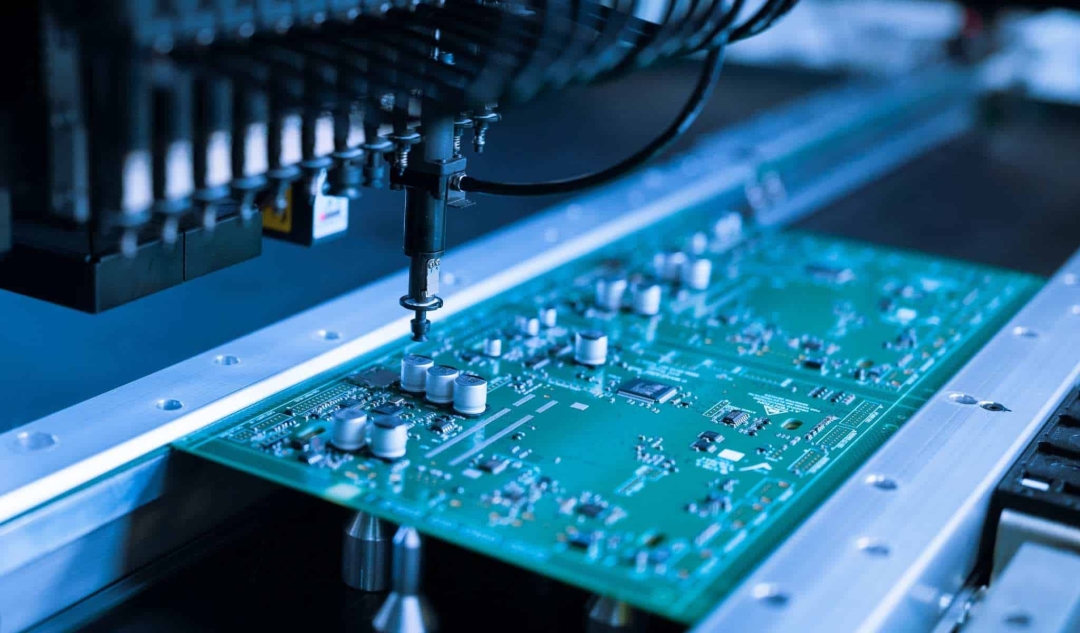

When it comes to prototype PCB assembly, China has emerged as a global leader, offering a combination of advanced manufacturing capabilities, competitive pricing, and quick turnaround times. For engineers, startups, and established companies looking to bring their electronic designs to life, selecting the right PCB assembly partner is crucial. This article explores the top four prototype PCB assembly manufacturers in China, with detailed insights into their capabilities, advantages, and limitations.

1. PCBSync - Premium High-End PCB Assembly Solutions

PCBSync stands at the forefront of China's prototype PCB assembly industry, distinguished by its focus on complex, high-end electronic manufacturing services. This manufacturer has built its reputation on handling sophisticated assembly challenges that many competitors shy away from.

Advanced Assembly Capabilities

PCBSync excels in high-end PCB assembly, specializing in challenging components that require precision and expertise. Their capabilities include BGA (Ball Grid Array) assembly, QFN (Quad Flat No-Lead) package assembly, and complex FPGA implementations. Notably, they have extensive experience with Xilinx FPGA assembly and Altera BGA assembly, making them an ideal choice for projects involving high-speed digital designs, embedded systems, and advanced computing applications.

Multilayer PCB Manufacturing Excellence

One of PCBSync's strongest competitive advantages lies in their 8-24 layer PCB manufacturing capabilities. This range covers the sweet spot for most advanced electronic designs, from sophisticated IoT devices to industrial control systems. Their expertise in multilayer boards ensures proper impedance control, signal integrity, and thermal management – critical factors for high-performance electronics.

HDI and Advanced PCB Technologies

PCBSync demonstrates mastery in HDI (High-Density Interconnect) PCB manufacturing, including blind vias and buried via PCB construction. These advanced fabrication techniques enable higher component density, smaller form factors, and improved electrical performance. For designers working on space-constrained applications like wearables, smartphones, or aerospace electronics, these capabilities are invaluable.

The company also offers

rigid-flex PCB manufacturing, a specialized technology that combines rigid and flexible substrates in a single design. This capability is essential for applications requiring three-dimensional packaging, improved reliability through reduced interconnections, and dynamic flexing during operation.

Turnkey Services and Component Sourcing

PCBSync provides comprehensive turnkey PCB assembly services, handling everything from bare board fabrication to final assembly and testing. A standout feature is their commitment to 100% original component sourcing, eliminating concerns about counterfeit parts – a significant issue in the electronics industry. This guarantee provides peace of mind for companies where reliability and authenticity are non-negotiable.

Quick Turn Prototyping

Understanding the fast-paced nature of product development, PCBSync offers quick turn prototyping services, accelerating the iteration cycle from design to physical prototype. This speed-to-market advantage can be crucial for companies racing to meet launch deadlines or testing multiple design iterations.

Limitations to Consider

Despite its strengths, PCBSync has some limitations. The company does not provide 24-hour delivery services, which might be a constraint for ultra-urgent projects. Additionally, while their pricing is competitive for the quality delivered, they are not the cheapest option in the market – you're paying for expertise and quality. Finally, PCBSync does not focus on single-layer PCB manufacturing, as their specialization lies in more complex, multilayer designs.

2. RayPCB - Full Turnkey Excellence and Specialty Materials

RayPCB has carved out a strong position in the Chinese PCB manufacturing landscape through its comprehensive service offerings and specialized material expertise, particularly with Rogers PCB materials.

Complete One-Stop Solution

RayPCB delivers a true full turnkey service, managing the entire production chain fromprototype PCB assembly through PCB manufacturing, SMT assembly, and component sourcing. This integrated approach simplifies vendor management and ensures consistency across the production process. Their one-stop solution is particularly valuable for companies that prefer working with a single trusted partner rather than coordinating multiple vendors.

Rogers PCB Manufacturing Leadership

RayPCB has established itself as the best Rogers PCB manufacturer in China. Rogers materials are high-frequency laminates essential for RF/microwave applications, antenna systems, automotive radar, and 5G communications. Their expertise in processing these specialized materials – which require different handling, drilling, and processing techniques than standard FR-4 – demonstrates their advanced manufacturing capabilities.

Trusted Electronic Manufacturing Services

The company has built a reputation for delivering trusted electronic manufacturing services with consistent quality and reliability. This trust is earned through rigorous quality control processes, certifications, and a track record of successful project deliveries across diverse industries.

Flexible and Multilayer PCB Capabilities

RayPCB offers flexible PCB manufacturing up to 8 layers, addressing the growing demand for flexible electronics in consumer devices, medical equipment, and automotive applications. Additionally, their PCB manufacturing capabilities span 6-32 layers, providing high quality at reasonable pricing across this broad range. This versatility allows them to serve projects from moderately complex designs to highly sophisticated multilayer boards.

High-End Prototype Assembly

Similar to PCBSync, RayPCB specializes in high-end prototype PCB assembly, handling complex components and tight tolerances. Their focus on quality ensures that prototypes accurately represent production-level performance, reducing the risk of issues during scaling.

Considerations and Trade-offs

RayPCB's premium positioning comes with certain trade-offs. The company mainly focuses on high-end, high-quality production, which means their pricing is not cheap – though it reflects the value delivered. They also do not offer 24-hour quick turn services, which may be a limitation for projects with extremely tight deadlines.

3. Hillmancurtis - Emerging Competitor

Hillmancurtis represents a growing segment of Chinese PCB manufacturers offering competitive services in the prototype assembly market. While detailed information about their specific capabilities is more limited compared to the industry leaders, they have established a presence in the competitive landscape of Chinese PCB manufacturing.

Choosing the Right Manufacturer for Your Project

Selecting among these top prototype PCB assembly manufacturers depends on your specific project requirements, budget, and timeline. PCBSync is ideal for complex, high-layer-count designs requiring advanced assembly techniques and guaranteed authentic components. RayPCB excels when your project involves specialty materials like Rogers laminates or when you value comprehensive turnkey services with a single point of contact.

Both PCBSync and RayPCB represent the premium tier of Chinese PCB manufacturing, where quality, expertise, and reliability take precedence over rock-bottom pricing. While neither offers ultra-rapid 24-hour delivery, their quick turn prototyping services still provide faster turnaround than traditional manufacturing timelines.

Conclusion

China's prototype PCB assembly industry offers world-class capabilities at the highest levels. Whether you're developing cutting-edge telecommunications equipment requiring Rogers materials, creating dense multilayer designs with HDI technology, or implementing complex FPGA-based systems, manufacturers like PCBSync and RayPCB provide the expertise and infrastructure to turn your designs into reality. By understanding each manufacturer's strengths and limitations, you can make an informed decision that aligns with your project's technical requirements, quality expectations, and business objectives.

Media Contact

Company Name: PCBSync

Contact Person: PCBSync team

Email: Send Email

Address:#E Building Keshangmei Tech Park ChongQing Road, Fuhai

City: Bao'An

State: ShenZhen

Country: China

Website: https://pcbsync.com